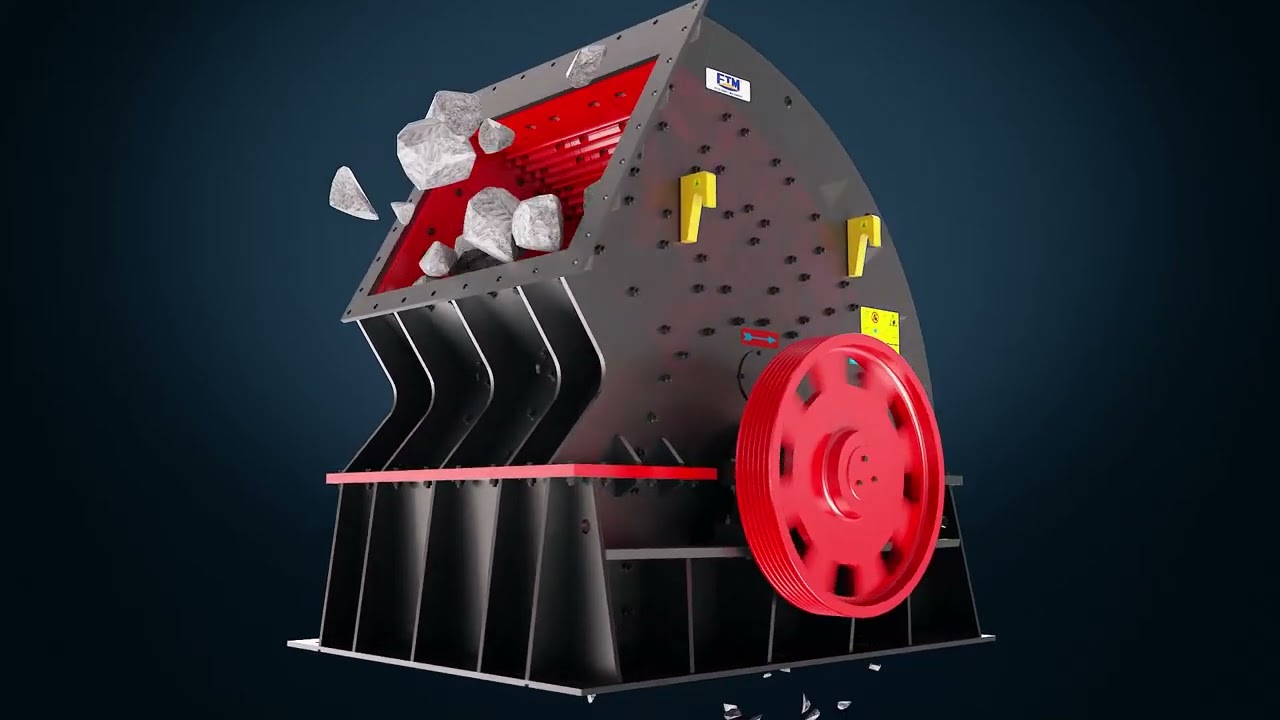

The hammers of stone crushers are important in the process of crushing rocks, gravel, and stones that are used in the construction of roads and also in the extraction of products like gravel. These machines are subject to constant impacts and friction because they tend to smash hard materials into smaller sizes that can be used. Due to this reason, the tips of the hammers wear easily, causing replacement and increased cost of maintenance. To address this problem, several stone crusher manufacturers and operators are currently using carbide mulcher teeth. These teeth are made using tungsten carbide tips, which are capable of extreme pressure, heat, as well and wear. No matter what you are doing on a busy quarry or a big road construction project, carbide mulcher teeth can be used to ensure that the stone crusher hummer works longer and more efficiently, even in the most difficult circumstances.

Why Stone Crusher Hammers Need Stronger Teeth

Stone crushers are mostly applied in tasks that are rigorous and demanding, as they are employed to crack hard rocks and stones to be used in construction or land development. With each swing of the hammer, it is subjected to great impact forces. With time, the ordinary steel hammers become dull and weak in power and produce unevenly and more slowly. Others possess minerals that can also easily erode metal surfaces. The crushers are often used to handle mixed materials such as gravel and concrete, which can be even more abrasive in road projects. Worn-out hammers will have to be replaced, which, again, requires downtimes and additional costs. This is where carbide mulcher teeth come to the rescue. The special construction enables them to remain sharp and strong at the end of an extended period of use. They safeguard the hammer part, decrease servicing, and enhance crushing performance.

Performance in Quarry Operations

The quarrying activities require continuous performance of machinery. Machines are required to process large amounts of rock on a daily basis. Downtime may be expensive in such settings. The frequent hammers are usually worn out, and the operators need to halt and with a new part, but Carbide mulcher teeth are made to be enduring. Stone crusher hammers have high wear resistance and are therefore capable of crushing thousands of tons of material without loss of efficiency. Carbide tips do not chip or crack regardless of striking hard granite or limestone due to their ability to remain sharp longer, resulting in a steady amount of output that is consistent, resulting in standard crushed material meeting the output specification needed in construction projects. Such dependability is one of the key reasons why the quarries in the world currently turn to the use of carbide-based crushing tools.

Use in Road Construction and Land Development

Stone crusher hammers find application in the preparation of gravel, crushed rocks, and base materials in the construction of foundations and in road construction. Such projects usually demand the use of the crusher during mixed work, which involves the use of stones, soil, and compacted ground. Carbide mulcher teeth are particularly effective in these situations. They can work both the hard rock and the soil with the same effectiveness, which enables the crusher to work at a high output without changing the tool frequently. They also resist heat, thus avoiding deformation or wear due to repeated impact in case of land reclamation or rural development, stone crushers with carbide teeth are employed to clear fields and prepare surfaces. The teeth chop big stones into small ones, which can be easily processed or used as roadbeds. This assists in accelerating the projects as well as lowering the overall operating costs.

Manufacturing Strength and Compatibility

The results of carbide mulcher teeth are determined by the material as well as their manufacture. Quality teeth undergo precision forging, brazing, and heat treatment in order to be able to push them to extreme working loads. The steel body is normally prepared by the use of alloy steel 42CrMo or 40Cr, and the tungsten carbide is therefore welded with the steel at high temperatures to form a strong bond that ensures the tip does not loosen when in use. To fit in a varied industry, the teeth of the carbide mulcher are carefully tested to be of standard hardness as well as 40-45 HRC. This compatibility enables operators to upgrade old machines and does not change them with significant alterations, making them perform better instantly.

Conclusion

The carbide mulcher teeth have been a major component of the modern stone crusher hammers used in quarry as well as in road construction projects. These carbide-tipped tools are much more effective than conventional steel hammers due to their hardness, ability to withstand heat, and prolonged lifespan, which allows them to cut even when the machine is in extreme conditions, thus saving money in maintenance costs and staying longer in service. Carbide mulcher teeth in stone crushers are not only strong, but also designed to help meet consistent performance and dependable results, regardless of what is being done to the land, whether it is quarrying, road building, or clearing the land.